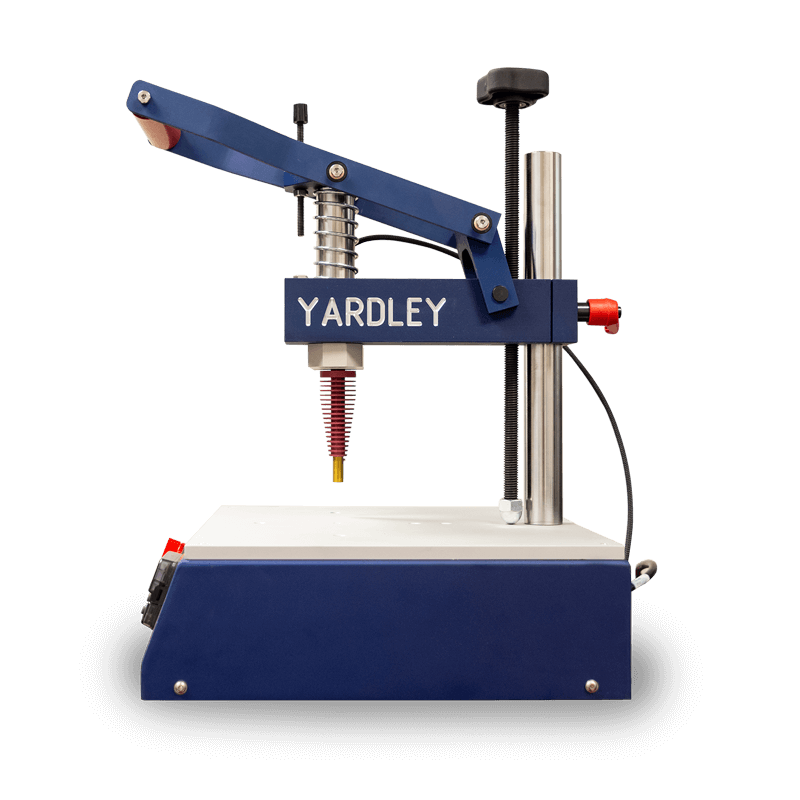

Yardley Inserts, the U.S. based manufacturer of high quality threaded metal inserts, officially released its all-new digitally enhanced Thermal Inserting Press 2.0 for purchase.

The Thermal Inserting Press 2.0 provides manufacturers the ability to circumvent the typically expensive and complex ultrasonic equipment required to install threaded metal inserts into thermoplastics. For users working on 3D printing, prototyping, or low volume production, the Thermal Inserting Press provides an inexpensive option requiring little investment and space to produce the same quality end-result.

The new version of Yardley’s Thermal Inserting Press also includes an all-new digital display with digital controls, to allow for very accurate temperature control. The ability to control the temperature prevents damage to plastic while also providing a strong, permanent installation of inserts with high resistance to rotation and pull-out.

“As a manufacturer of premier threaded metal inserts and insertion tools, Yardley Inserts has strived to take steps to improve our products that will directly impact our customers. The Thermal Press 2.0 is another step in that direction,” said Ken Grady, General Manager of Yardley Inserts. “The new digital display will allow users to more precisely control the temperature of the thermal press, allowing for a cleaner application. This product will save manufacturers hours of time, and a huge amount of space on their shop floors.”

The Thermal Inserting Press 2.0 can be upgraded to fit your specific needs. Not only can it be used to install inserts into plastics, but it can also be custom to do other tasks such as removing inserts from plastics and heat staking.

Due to increased demand, Yardley Inserts reached out to James Stern, Vice President at Trinetics Group, for a way to increase production of the thermal installation tool. While developing a more efficient way of producing the thermal press, Stern and his team also took the initiative to improve the original version of the thermal press.

Along with updating the digital display for accurate temperature control, Trinetics incorporated other updates to make the process of using the thermal press more repeatable, including an improved arm linkage.

“We made the arm linkage simpler to make the process of pressing inserts much smoother,” said James Stern. “At the same time, we decreased the amount of pressure required but made sure the arm provided plenty of resistive feedback, allowing for a consistent install.”

All of the painted parts were also upgraded to hard, anodized parts, giving the thermal press a higher quality finish.