Yardley Inserts LLC, a manufacturer of precision-engineered threaded metal inserts for a wide range of fastening applications, provides custom solutions for aerospace, appliance, automotive, defense, electronics, and other industries. Yardley’s low-lead brass threaded inserts provide manufacturers with an eco-friendly solution that is both reliable and environmentally safe.

Yardley Inserts LLC, a manufacturer of precision-engineered threaded metal inserts for a wide range of fastening applications, provides custom solutions for aerospace, appliance, automotive, defense, electronics, and other industries. Yardley’s low-lead brass threaded inserts provide manufacturers with an eco-friendly solution that is both reliable and environmentally safe.

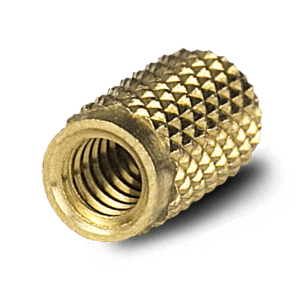

The low-lead brass threaded inserts provide good machinability, excellent forgeability, and are usable in numerous applications. In an effort to drastically reduce lead poisoning in drinking water, the federal government implemented new lead restrictions for plumbing applications. As of 2014, all potable plumbing components (i.e. pipes, faucets, valves, etc.) shall have a weighted average lead content of 0.2 percent lead or less. These low-lead brass inserts offer an environmentally friendly advantage that will comply with this new code, while still maintaining a high quality. The specially formulated lead-free brass alloy slightly adjusts the lead content and keeps the machinability, ductility, and wear resistance properties brass provides.

The low-lead brass threaded inserts are also ideal for medical applications due to their non-magnetic properties for medical instruments and laboratory test equipment.

Along with providing low lead brass threaded inserts to cut down on lead pollution, Yardley Inserts implemented new practices to lessen their environmental impact. In a collaborative effort between Yardley and its suppliers, chlorinated oil, grease, and detergents were removed from their processing. These lubricating agents were replaced with high synthetic, non-chlorinated cutting oil to keep tools running smoothly and efficiently while reducing Yardley’s ecological footprint.

“Yardley and our suppliers came together to figure out the best solutions to become greener,” said Ken Grady, Vice President at Yardley Inserts. “It was a real ‘gathering of the minds’ to find ways to make our manufacturing more eco-friendly. We are proud to be adding these practices along with our REACH, WEEE, and ROHS certifications to reduce our environmental footprint.”

Further, Yardley Inserts is cutting down on energy consumption by replacing all overhead lights in their facilities with LED bulbs. This will reduce carbon dioxide emissions. By making these small changes, companies like Yardley Inserts and their suppliers can make a big difference in reducing waste and promoting environmentally responsible practices across the manufacturing industry.

Learn more about our low-lead brass threaded inserts.

To request a quote, discuss your application, or request a free sample of Yardley threaded metal inserts, visit our contact us page or call us toll-free at 800-457-0154.