3D printing is the future of manufacturing. While there are many ways to attach multiple 3D printed parts together, nothing quite compares to using genuine metal threads.

3D printing is the future of manufacturing. While there are many ways to attach multiple 3D printed parts together, nothing quite compares to using genuine metal threads.

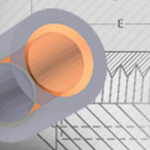

Yardley Inserts has been supplying threaded metal inserts for use in 3D printing and rapid prototyping. Through our experience, we’ve discovered that for some applications, metal threads are an absolute must. If you need to repeatedly attach and detach components and want robust mechanical fastening, threaded metal inserts are the way to go. Here are a few good ways to incorporate metal threads into your 3D printed parts.

Add a hexagonal pocket onto your 3D printed parts. The pocket will serve as a place to press-fit a hexagonal nut onto the part. You can also choose a square pocket and nut for extra twist-out strength. Make sure to design in a 0.1 mm offset around the nut as well as a clearance hole for the insert.

If you need a solution that isn’t as permanent, printing the threads can be a solution. While these types of threads will be more delicate, leaving the part in the sun after printing can help avoid such issues. Follow up with a tap or use an insert or nut to clean up the threads.

Manufacturers recognize 3D printing reduces design, prototyping and production time, which is why our customers are integrating threaded metal inserts into 3D printed fixtures and molds. This is a cost-effective way for manufacturers to test threads and adjust insert holes during various design iterations.

Yardley Inserts offers technical data to assist with the prototyping process. You can also reference our corresponding 2D and 3D downloadable CAD drawings to spec out threaded insert applications.

To request a quote, discuss your application, or request a free sample of Yardley threaded metal inserts, contact Yardley Inserts toll-free at 800-457-0154.